Arm powers over 125 billion chips in devices around the world, and researchers at the global technology giant are constantly working with partners to shape a secure and connected digital world, with intelligence at the core.

An integral part of the ARM philosophy is to fuel technology transfer between academia and industry; and this autumn marks the 10th anniversary of an award-winning partnership with the University of Southampton.

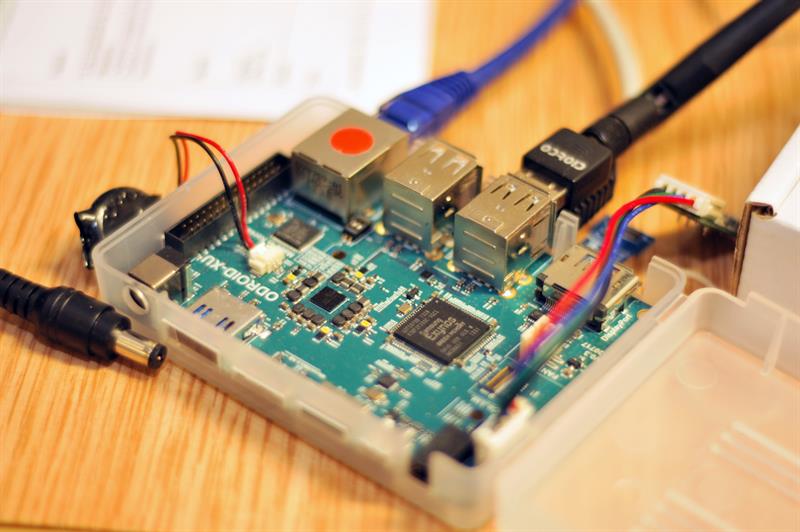

The Arm-ECS Research Centre, based in the Russell Group University’s School of Electronics and Computer Science (ECS), focuses on advanced design methods, architectures and their practical validations for energy-efficient and dependable single-core and multi-core processor systems.

“Our researchers are creating the future of mobile and embedded systems,” Arm Research Group Leader, Stephan Diestelhorst, explains. “Arm’s technologies are demonstrating the Centre’s research findings: our test chips allow researchers to practically validate new designs and approaches, while our software tools are released to the community so that others can benefit from our results and methodologies.”

To date, the Centre has fabricated 12 new test chips, released 3 open source tools, collaborated on co-authoring 32 papers, graduated 6 co-supervised PhD students and completed 22 internships in Cambridge. The collaboration’s accomplishments have also been recognised with a University Research Group of the Year award from Techworks (formerly the National Microelectronics Institute) in 2015.

“One of the main objectives for the Centre is to ground academic research in a real-world environment – using the experience and requirements of an industrial partner to guide and focus research projects,” explains Associate Professor and Centre Technical Manager (ECS) Geoff Merrett. “Over the past decade Arm-ECS has become a model of industry-academic collaboration done well.”

Where industry and academia meet

The Centre, which is co-directed by ECS’s Professor Bashir Al-Hashimi CBE and Arm Director of Technology Professor David Flynn, requires input from both academics and industrialists on projects, with the nature of research steered by the expected needs and requirements of Arm. This covers shorter-term issues of concern, but also more ‘blue sky’ research, which might be harder to justify solely for a company.

The Centre has become one of Arm’s largest university research collaborations in the UK and contributed to Bashir Al-Hashimi’s recognition in the Queen’s Birthday Honours 2018, awarded for his services to engineering and industry.

“I think it’s crucial for academia to establish a relationship with an industrial partner,” says Prof Al-Hashimi. “Arm has recognised the quality of the research we undertake here at Southampton, Over the past ten years we have developed a regular internship programme, which has helped expose us to the latest and current thinking at Arm. My job is then to align this with our academic research.”

One line of research being investigated by Arm-ECS engineers is in the field of energy harvesting. With the demand for IoT sensors forecast to rise in coming years, researchers view energy harvesting as a promising solution.

The technology is currently associated with a number of issues such as intermittent supply, component variability and low power output. However, it is believed these could be addressed with a combination of innovative solutions.

The research team, which includes Dr Geoff Merrett, Dr Alex Weddell and PhD students Tim Daulby and Sivert Sliper from ECS, with Staff Engineer Anand Savanth and Senior Principal Engineer James Myers from Arm, is exploring creative options such as adapting computation to the energy available, coping with variations in the harvested power.

Another current case study from the Centre is the development of a new low-power flip-flop. The device was initially created by PhD student Yunpeng Cai during his studies at ECS and developed into a robust design while on his internship at Arm Research, Cambridge.

Initial silicon results with the contention-free design incorporated into the Pipistrelle 4 test chip show significant power and area benefits. A patent for the new single-phase clocked flip-flop, constructed from as few as 18 transistors, has recently been granted.

Collaborative research

The success of projects in the Arm-ECS Centre has also led to subsequent wider, collaborative research with a broader set of academic and industrial partners, across the UK and Europe. The EPSRC’s £5.6 million PRiME research programme is a collaboration of four UK universities and five industrial partners – Altera, ARM, Freescale, Imagination Technologies and Microsoft Research – researching methods to reduce the power consumption and increase the reliability of future many-core embedded systems.

The 10th anniversary of the Arm-ECS Research Centre was recently marked with a reception at Robinson College, Cambridge. The celebration, which followed the conclusion of the Arm Research Summit, showcased recent successes from the Centre.

These included advances by PhD student Matthew Walker, whose involvement in Arm-ECS has innovated accurate and stable run-time power modelling for mobile and embedded CPUs.

His statistically sound approach to run-time power estimation was nominated as an Institute for Electrical and Electronic Engineers (IEEE) Transactions on Computer-Aided Design of Integrated Circuits and Systems (TCAD) Best Paper and provided the foundation for the publicly available, free and open-source tools PowMon and GemStone.

| “The ECS aims to ground academic research in a real-world environment, using the experience and requirements of an industrial partner to guide and focus its research.” - Geoff Merrett |

PhD research projects are a key aspect of the Arm-ECS relationship, with each early career researcher supported by one or more industrial mentors from Arm in addition to the academic supervision from ECS. This unique research experience includes the opportunity to intern with Arm in Cambridge.

Current PhD student Ben Fletcher is exploring low cost 3D integration for the IoT and is now based at ARM’s Cambridge office, having spent the first half of his study in Southampton.

“Three dimensional integrated circuits are a new breed of silicon chips that contain multiple layers of silicon stacked up vertically,” Fletcher explains. “Integrating multiple layers will mean that they can incorporate more diverse functionality and also function quicker, whilst consuming less power. My research is specifically looking at innovative ways of communicating data between the layers within these new stacked 3D-ICs using wireless communication through inductive coupling.”

The success of the Arm-ECS Research Centre has demonstrated a model that could be replicated by other universities and prospective industrial partners across the UK says Prof. Al-Hashimi.

“It’s been built on delivery and trust and is a strikingly professional working relationship, that is helping us attract some of the brightest students from around the world and which adds to the value of their research and their long-term employability.”