Characteristics of ultrasound

Ultrasound is an acoustic wave with a very high frequency, beyond human hearing. Since the audible frequency range is said to be between 20Hz and 20kHz, ultrasound generally means acoustic waves above 20kHz. Bats, with their echo-location (biological ultrasonic radar), can hear sounds up to 200kHz, way beyond the capabilities of the human ear.

Ultrasound has several characteristics which make it so useful and that have led to its use in many electronics applications. Firstly, it is inaudible to humans and therefore undetectable by the user. Secondly, ultrasound waves can be produced with high directivity. Thirdly, they are a compressional vibration of matter (usually air). Finally, they have a lower propagation speed than light or radio waves.

The fact that ultrasound is inaudible to human ears is an important factor in ultrasound applications. For example, a car parking sensor system generates sound pressure of more than 100dB to ensure clear reception. This is the equivalent of the audible sound pressure experienced when standing close to a jet engine.

Ultrasound's high frequency (short wavelength) enables narrow directivity, similar to its radio wave equivalent, microwaves. This characteristic is used in kidney stone treatments, where ultrasound emitted from outside the body is focused on the stone to break it down. Since the energy level is low, it does not harm the body.

Because ultrasound is a vibration of matter, it can also be used to examine the characteristics of that matter. Ultrasonic diagnosis uses this feature to detect and visualise the variance in reflectance and transmittance corresponding to the water content and density of the matter in the medium, for example an organ in your body.

Ultrasound travels in the air at around 340m/s like other sounds. The time it takes for an ultrasound wave to travel 10cm is approximately 3ms, as opposed to 3.3ns for light and radio waves. This allows measurement using low speed signal processing.

Ultrasonic sensors for parking

Let's look at parking sensors as an example. Parking sensors use a type of sonar. The term sonar is an acronym for sound navigation and radar; it's used for calculating the distance and/or direction of an object from the time it takes for a sound wave to travel to the target and back. An ultrasonic sensor is a speaker or microphone that emits or receives ultrasound. There is also a type that can handle both emission and reception. Vehicle parking sensors are equipped with this type of sensor.

Ultrasound sensors initially found use in vehicles for detecting obstacles when parking (Figure 1) but it is now evolving into an automatic parking system.

Figure 1. Examples of parking sensor systems in vehicles

This system controls steering, acceleration and braking automatically, based on the parking zone and location information gained from the ultrasonic sensor, to achieve parallel parking and garage parking.

In the case of the rear sonar, two to four ultrasonic sensors are mounted on the rear bumper to detect an obstacle up to 2 to 2.5m away. The distance is communicated to the driver in real time using varying buzzer sounds. Even a wire fence can be detected if it is close enough.

The main characteristics of ultrasonic sensors for rear sonar are directivity, ringing time, sensitivity and sound pressure.

Directivity of an ultrasonic sensor corresponds to the size and shape of the vibrating surface (that is emitting the ultrasound) and the frequency at which it vibrates. Figure 2 indicates directivity of a disc type transducer.

Figure 2. Emitting surface diameter and directivity (calculated value) for disc type transducer

Narrower directivity can be achieved at higher frequency when the size remains the same, or at larger size when the frequency remains the same. Difference in detection distance with varying frequency at the same size is indicated in Figure 3.

Figure 3. Frequency (directivity) and influence of the ground

By using higher frequency and selecting an appropriate amplifier (gain), we can increase the influence of ground objects, such as wheel stoppers. While narrower vertical directivity improves sensor usability, wider horizontal directivity can provide wider coverage with fewer sensors. 'Asymmetric' ultrasonic sensors (Figure 4) are used in such situations.

Figure 4. Directivity type for ultrasonic sensors

Since rear sonar ultrasonic sensors handle both sending and receiving of ultrasound, unless the emitting sound wave dissipates without ringing quickly, it cannot start receiving its reflection. The shorter the ringing time, the closer the detection range can be.

The casing for Murata's ultrasound sensor, which also acts as an ultrasound emitter, is precision made to resonate with the driving frequency. This is the reason for its high sensitivity and sound pressure.

Figure 5 shows ultrasonic sensor MA40MF14-5B, most frequently used for vehicle sonar, and its directivity.

Figure 5. MA40MF14-5B and its directivity

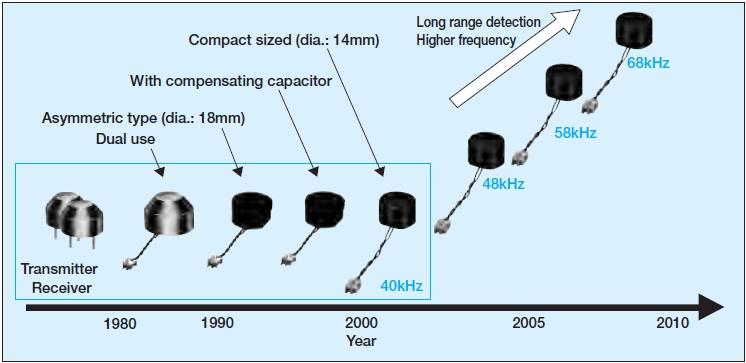

It is characterised by asymmetric directivity (110o x 50o), short ringing time and high sound pressure, sensitivity and reliability. In addition to a 40kHz nominal frequency model, its line-up also includes 48kHz, 58 kHz and 68kHz models.

Application example

Ultrasonic sensors are driven by intermittent waves called burst waves. Burst waves normally have 20 cycles of repeating waves with the same frequency as the nominal frequency of the sensor. Furthermore, the interval between bursts must be sufficiently longer than the time it takes for the wave to reflect back from the target.

Figure 6 is an example of the sensor circuit for a typical parking sensor system.

Figure 6. Example of a sensing circuit

Since these sensors must be waterproof, they are less sensitive than sensors for indoor use. For this reason, the sensor's driving voltage must be increased to 70 to 100V using a transformer to emit a stronger ultrasound.

The transformer inductance on the sensor side acts as a component of an LC parallel resonant circuit to reduce ringing at reception. Inductance of the transformer is derived from 1/[(2wf)2C] where f is the resonant frequency. The transformer can be designed easily since the step-up ratio and the number of turns are determined by driving voltage and inductance, respectively.

However, sensor capacitance fluctuates greatly as the temperature changes due to temperature characteristics of the piezoelectric material and the difference in thermal expansion coefficients between the piezoelectric element and the casing. Murata has minimised this temperature dependent capacitance fluctuation by connecting a capacitor with the opposite temperature characteristics (a temperature compensating capacitor) in parallel with the piezoelectric element.

This enables short, stable ringing characteristics over a wide temperature range. This technology is essential for a system capable of detecting an object at short distance of approximately 10cm.

Lastly, the evolution of ultrasonic sensors for vehicle parking applications is shown in Figure 7.

Figure 7. Evolution of ultrasonic sensors for rear sonar

Nearly half the new vehicles in Europe and Asia have rear parking sensors. This technology is expected to gain popularity in North America as well. We hope to help improve the safety and comfort of vehicles through the use of ultrasonic sensors.

Author profile

Munenori Hikita is Murata's European product manager for sensor products.