Technology is moving ever faster and the market rewards early entrants. But these shortened product development cycles mean that all aspects of development, including test and validation, become increasingly important. While the pressure to get products to market is high, technologies such as USB Type-C only increase the complexity of testing. Understanding the connector helps to identify those areas where additional tests, instruments and test fixtures are needed. Getting it wrong can easily extend your test time and cost. If your device fails at a USB-IF compliance workshop, the cost and time delay will be even higher.

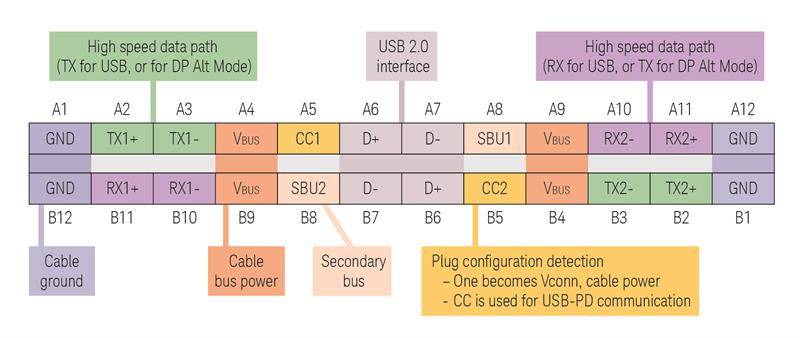

| The USB Type-C 24 pin specification |

Figure 1 shows the 24 pin connection of USB Type-C. The power pins –VBUS and GND – support up to 5A/20V (100W), while the four transmit/receive (TX/RX) pairs allow for one, two or all four channels to be used for data transmission at any time and support up to 20Gbit/s per lane. The CC1 and CC2 lines manage the definition of the connector interface by providing three functions: orientation configuration management; supply power to cable; and communication channel for power delivery. The side band communication channels SBU1 and SBU2 provide additional connections and can be used for protocols other than USB. A simultaneous link of USB 2 (D+, D-) can be used for standard USB 2 operations or as a supplemental link providing information for power delivery. The D+ connections are tied together, as are the D- connections to maintain the orientation independence of the connector.

Power Delivery (PD) manages the power allocations dynamically, adjusting voltage and current and establishes provider/consumer roles for all connected devices. These devices can request the power they need and get more power when required for a specific application. PD is bi-directional, making it possible for a device being powered to also supply power to other devices. PD also enables USB Type-C to support other standards, such as DisplayPort (DP) or Thunderbolt (TBT) through Alt mode.

USB Type-C test challenges

Design and test engineers face several challenges as they update their device interface from the 4pin USB standard A/B to the 24pin USB Type-C connector. USB Type-C includes design changes that address issues with A/B type connectors/cables and offer more features and capabilities for USB Type-C enabled products. Understanding test challenges and solutions can help ensure successful USB Type-C integration and test for devices.

| "Understanding the connector helps to identify those areas where additional tests, instruments and test fixtures are needed." Erik Babbé, Keysight Technologies |

- Power delivery

PD’s dynamic ability and range of possible power configurations, combined with the added challenge of evolving specifications for USB 2.0, USB 3.1 Gen 1 and Gen 2, and PD compliance, make USB Type-C device test validation more challenging than traditional USB test. Power, PHY layer and protocol layer remain the key test categories for compliance test. Important test parameters design engineers must consider include different voltage levels, device charging, cable functionality and determination of provider versus consumer device status.

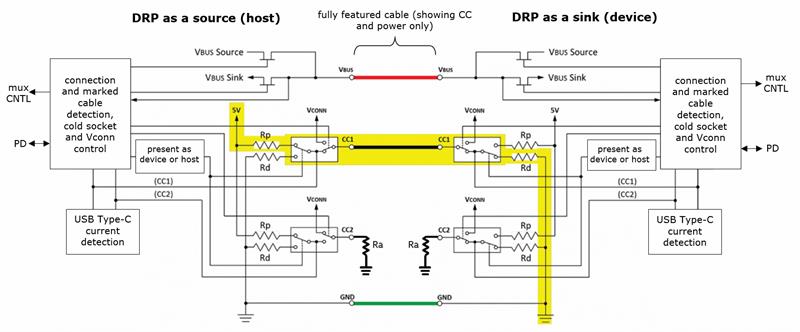

Figure 2 shows the host and device as dual role ports (DRP). This is aligned with the USB Type-C environment, where roles can be swapped. The state of a DRP – host or device – is managed by the CC line as a part of the PD infrastructure. Debug of the PD protocol is one of the biggest challenges since it requires access to the CC lines and the VBUS signal for proper characterisation. USB PD has specified voltage/current levels that devices can select for operation, making the ability to test PD levels as devices initialise important.

An example configuration for physical layer device test includes an oscilloscope, probes, current probe, USB PD protocol software, coupons/fixtures and a PD controller. With 300kHz data transfer rates, an oscilloscope of 500MHz or better is recommended, along with long record length to capture the entire packet. Although predominantly DC signals, most have AC characteristics and this requires a scope with adequate bandwidth. A probe offset is recommended in order to see signal transients when analysing the 5V DC supply signal as a DC block filters out DC and low frequency content.

- Transmit/receive

USB Type-C specifications introduce new TX and RX test challenges. The ability to measure quickly and accurately key aspects of the transmitted eye, LFPS and LBPM timing, transmitted SSC profile, SCD signals will be critical, as will the ability to perform de-emphasis and pre-shoot. Flexible signal generation and bit error detection are also key for RX test validation.

TX and RX compliance testing requires running compliance test patterns. These signal patterns are generated during compliance tests, while measurements are made in SigTest. Each compliance test presents individual challenges. USB-IF compliance testing will require many loading and charging conditions which increases the number of tests engineers must configure and execute.

For TX compliance test of USB 3.1, DP 1.3, TBT 3 and MHL, the N7015A and N7016A Type-C test fixtures are recommended for use with Keysight Infiniium oscilloscopes. This offers the best signal integrity, with a 20GHz bandwidth at -3dB and de-embeddable up to 30GHz. A Type-C plug interface fixture handles connector ‘flip’ and provides test point and probing access for transmitter and power delivery measurements.

The 16Gbit/s M8020A J-BERT offers such features as de-emphasis, pattern capabilities, continuous-time linear equalisation, decision feedback equalisation, the capability to create the various pattern structures and resequencing. The Keysight USB 3.1 receiver test solution provides accurate and repeatable test results, enabled by the M8020A’s calibrated jitter sources, precise emulation of pre- and post-cursor de-emphasis and inter-symbol interference traces.

- Cable and connector

USB Type-C channel specifications, including symmetrical connectors, high-speed data, high power, multiple data transmission types and backward compatibility, result in configurations that need to be tested to verify USB channel conformance. Performance of the channel in various configurations is also affected by loss, reflection and cross-talk. More rigour is needed than in the past to remove test fixture effects, to manage additional effects on channel response and to manage EMI and RFI levels.

Traditional cable/connector compliance tests have used a vector network analyser for frequency domain analysis and a TDR oscilloscope for time domain analysis. A new solution is Keysight’s ENA series network analyser with enhanced time domain analysis, measuring all compliance parameters. A microwave electronic calibration module can be used for ENA calibration and to remove the effects of the test setup.

The right solutions

Strong involvement in standards groups and related workshops, along with specification development has allowed Keysight to bring the right solutions to the market when needed.

In addition to being certified for all Type-C technology, Keysight’s solution provides: domain expertise; debug tools; single push of a button for full automation for all technologies; multiple power data objects; orientation automation; and 100W capability.

| USB Type-C full feature implementation |