One question we get asked quite frequently is about the suitability of running a power supply from a portable generator set.We tend to think of voltage waveform distortion and voltage noise spikes, but actually there are other issues that are of concern.

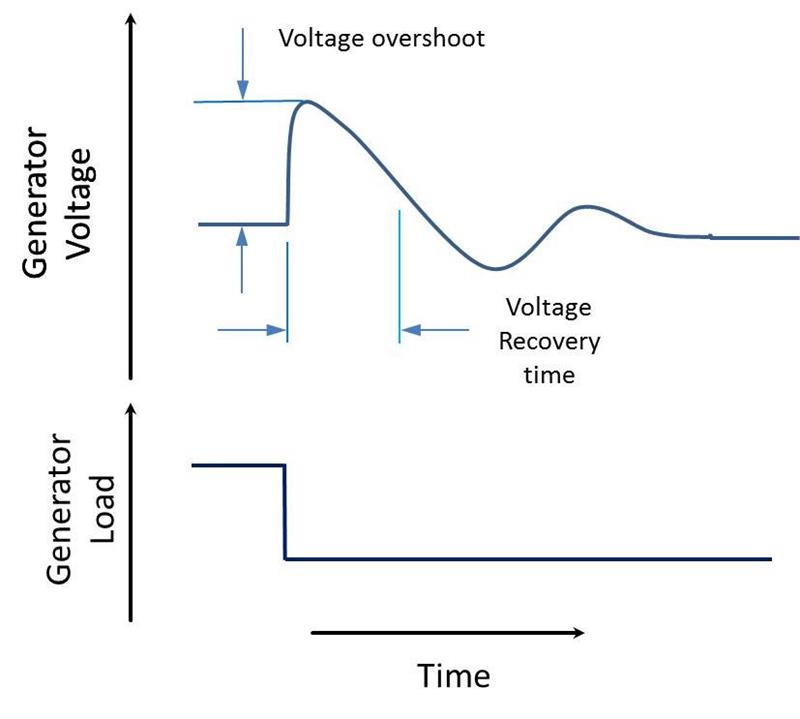

A back-up generator for a factory would normally be powering multiple load types, consisting of heating, lighting, machinery and office equipment.It would be unlikely that the loading on the generator would undergo sudden major changes.At an outdoor event though, this may happen - particularly at the end of a song or during a break in the event schedule.If this occurs there could be a brief, but substantial rise in the AC voltage when the generator suddenly sees a very light load.

Generator Voltage Overshoot with Load Change

Initially manufacturers specifying the use of generators had to rely on local country standards, but these did not always specify voltage and frequency deviations – just the ability to be capable of accepting and recovering from a full load step.Stability and response times are now categorised under the ISO 8528 (BS7698) standard with four performance standards listed in ISO 8528-1-7 for governor regulation.

Class G1 – Used for applications where the connected loads only require the basic parameters to be specified.This includes general purpose applications like lighting and electrical loads.

Class G2 – Required for applications where regulation is not that critical and temporary deviations are acceptable.Lighting systems, pumps, fans and hoists have some tolerance to frequency and voltage.

Class G3 – Applications where the equipment demands are moderately severe and includes telecommunications equipment and thyristor-controlled loads.

Class G4 – Required for applications where the demands are extremely severe.This typically includes data-processing and computer equipment.

The limits for these deviations are shown below.

| Class G1 | Class G2 | Class G3 | Class G4 | |

| Voltage Deviation 0-100% load change | <-25% | <-20% | <-15% | Custom* |

| Voltage Deviation 100-0% load change | <35% | <25% | <20% | Custom* |

| Voltage Recovery Time | <10s | <6s | <4s | Custom* |

*Class G4 systems are usually customer specified

Examining the impact of these voltages on various regions we get the following:

| North America (115Vac) | Class G1 | Class G2 | Class G3 | Class G4 |

Voltage Deviation | 86Vac | 92Vac | 98Vac | Custom* |

Voltage Deviation | 155Vac | 144Vac | 138Vac | Custom* |

| Voltage Recovery Time | <10s | <6s | <4s | Custom* |

| North America (208Vac) | Class G1 | Class G2 | Class G3 | Class G4 |

| Voltage Deviation 0-100% load change | 156Vac | 166Vac | 177Vac | Custom* |

Voltage Deviation | 280Vac | 260Vac | 250Vac | Custom* |

| Voltage Recovery Time | <10s | <6s | <4s | Custom* |

| Europe/China (230Vac) | Class G1 | Class G2 | Class G3 | Class G4 |

| Voltage Deviation 0-100% load charge | 172Vac | 184Vac | 195Vac | Custom* |

| Voltage Deviation 100-0% load charge | 310Vac | 288Vac | 276Vac | Custom* |

| Voltage Recovery Time | <10s | <6s | <4s | Custom* |

Most AC-DC power supplies are rated for 85 or 90Vac to 264Vac operation, but a number of manufacturers are now offering products that will accept 300Vac for five seconds.These products tend to be enclosed in a metal chassis, like TDK-Lambda’s RWS-B series, and are targeted at Industrial applications.

TDK-Lambda’s RWS-B series

From the tables above, products rated for 300Vac for five seconds can be used on Class G3 generators, and depending on the extent of the anticipated load changes, can probably be used with Class G2.

Open frame power supplies like TDK-Lambda’s ZMS100 tend not to have the 300Vac peak rating.This is because they are usually used in ITE (Information Technology Equipment) systems, where the end customer will request a Class G4 generator.

TDK-Lambda’s ZMS100 series

This does raise issues of concern, as mentioned earlier.

1)Designers of equipment who anticipate their product being used by diesel generators should consider using an industrial AC-DC power supply that has a 300Vac peak rating.

2)Manufacturers of the end systems should specify what class of generator their products should be used with.If they do see equipment failures when used with generators, they should question what class was used.Often the choice of generator will be that of the event organiser, who may lean towards the lowest cost!