TV makers, worried about the cost of making large screen sets using organic light emitting diodes (OLEDs) believe the quantum dot can get them close to the colour saturation of the slightly older technology at a fraction of the price. Although the best way to use quantum dots with LCDs in TVs would be to spray them across the entire screen, the colour saturation the elements can provide is good enough that they can be used more sparingly in the backlight elements – with monochrome LCDs used to filter the light into a convincing colour image.

The quantum dots have electron energy states that can be tuned to precise colours, such as the rich reds and greens needed for TVs. Excited by the high intensity blue-white LEDs commonly used in backlights, the dots produce brightly coloured light with a very narrow spectral profile.

| The ability to define the size of particles during manufacture allows precise control of their electronic and fluorescent properties. Courtesy: PlasmaChem |

Although the prototype TVs at CES propelled the quantum dot into the mainstream, their basic technology has already made it to production in a far less visible form – as a way of continuing the scaling of flash technology and allowing its integration with logic transistors. One example is the flash technology developed by Freescale for use on GlobalFoundries' 90nm process.

Older flash memory designs used three or four layers of oxide and conductor to form the programmable charge traps needed to capture and store electrons for long periods. Typically, the voltages are adjusted to allow energetic electrons to tunnel into a floating conductor layer and to then become trapped between layers of insulating oxide. As device dimensions reduced, the oxide layers became increasingly leaky, threatening to stop flash from being an effective non volatile memory.

One answer, as with deep submicron logic transistors, was to move to high-k dielectrics that could be made thinner without suffering from the same level of gate leakage as cheaper silicon dioxide. But thin layers are hard to make without defects, which can short-circuit the storage gate. Nanocrystals provided an answer by dividing the floating gate into many tiny gates operating in parallel. If a manufacturing defect was present in the gate, this could only affect a few of the nanoparticles and the rest would allow the device to function normally.

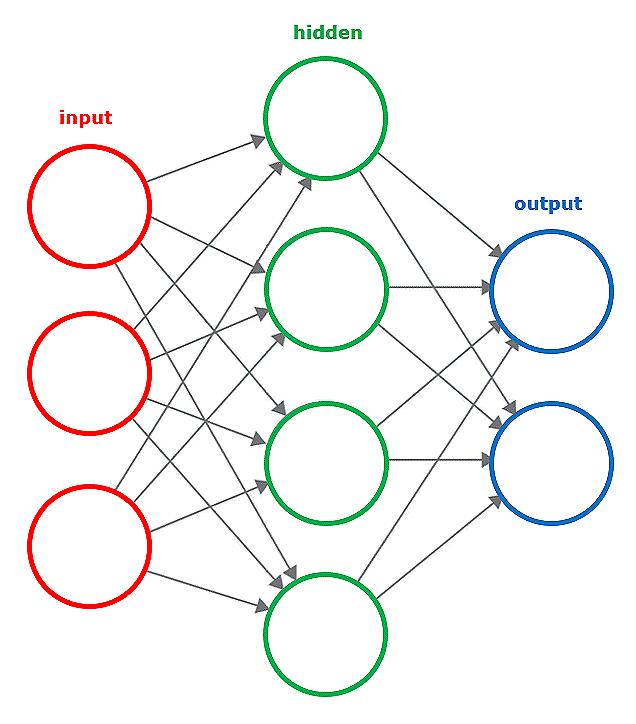

The theory of quantum dots extends the application of nanoparticles similar to those used in flash memory to a much wider array of potential uses. The key to the quantum dot is its confinement to a very small volume. Confinement in two dimensions is the distinguishing feature of heterojunction semiconductors, such as gallium arsenide or indium phosphide. Layers of the elements, formed using molecular beam epitaxy, are made so thin that, when active, the devices confine electrons travelling through them to just two dimensions.

The thickness of the layer needs to be smaller than the de Broglie wavelength of the electron – a property that is inversely proportional to the particle's momentum. The quantum dot extends the confinement to all three dimensions. As the electron orbitals of individual atoms effectively confine electrons to distances shorter than the de Broglie wavelength, quantum dots act – from the perspective of electrons – like artificial atoms. And this is one reason why physicists and electronics engineers are so interested in them – quantum dots provide a further way to tune material properties to suit specific applications and, potentially, to open up a new branch of materials science beyond the standard periodic table.

Like electrons in isolated atoms, electrons in quantum dots can only move between defined quantum states, which leads to the main interest that electronics engineers have in them. By controlling the size of quantum dots, it is possible to adjust the band gap between valence and conduction band electron orbitals. By changing the band gap, it is possible to alter the wavelength of light emitted when an excited electron loses energy and falls back into a lower state.

One demonstration of the effect of changing size on band gap – and therefore the wavelength of emitted photons – is provided by pictures of test tubes full of brightly lit colloidal solutions of nanoparticles that mimic the colours of the rainbow. At the blue end, the average nanoparticle diameter may be about 2nm; at the red end, it is 5nm. The chemical constituents of those nanoparticles remain the same, although some companies keep the particle size more or less constant and fine tune the chemical composition instead.

Unfortunately, it is not all good news. A key property for good optical properties is the relationship between the size of the nanoparticle and the excitonic Bohr radius – a measurement that determines the effective radius of an electron in a conduction band and the hole in the valence band it leaves behind. The higher the ratio between Bohr radius and nanoparticle size, the more pronounced the confinement effects, leading ultimately to heavily split valence and conduction bands.

The size of the excitonic Bohr radius of a commonly available semiconducting material, such as titanium dioxide, is just 1.5nm. But that of cadmium sulphide is almost twice as large. which means it ismuch easier to synthesise into nanoparticles with readily controllable diameters. But cadmium is a heavy metal poison, making its use in consumer electronics problematic, even though the amounts needed in backlights would be fairly small.

Another element suitable for making brightly coloured quantum dots is indium. But display makers have been trying to remove indium from existing designs – its oxide combined with tin is a transparent conductor – because the element is so rare.

As manufacturing methods improve, it may be possible to extend the range of elements that make suitable quantum dots. Further assistance may come from the relatively new discipline of computational materials science, in which software sifts through databases of material properties in attempts to find combinations of elements that might exhibit the required characteristics.

If materials scientists can expand the list of elements that can go into manufacturable quantum dots, many other applications could be lined up for them. Solar photovoltaic energy capture has been put forward as one major area because of the high quantum efficiency that highly confined materials can offer. Because the electrical activity is confined almost to a single point and does not demand that charge has to cross a region of doped silicon, very fast electronic switches may also be possible, as well as ultrafast photon-electron converters for optical networking.

The small size of quantum dots may also propel them into biomedical applications. Many diagnostic tools rely on fluorescent dyes that, today, are based on organic molecules that emit across a broad spectrum and degrade quickly. Although toxicity with many of today's quantum dot materials is a problem, this could change with further research. But it may take time for the next wave of quantum dots to emerge.