Harwin, the UK-based connector company, has just commenced construction of a new £30 million manufacturing facility to enhance its ability to serve multiple key markets and strengthen its ability to support innovation and meet growing customer demands.

This investment, however, is just part of a broader effort to improve its capabilities and services.

Last year Harwin quietly launched a new and highly intuitive standalone cable configuration tool which it had developed in conjunction with Cadenas, a software developer, to address strategic parts management and parts reduction.

Initially unveiled at electronica the Cable Configurator is intended to significantly reduce the time that engineers need to spend designing cable assemblies, allowing them to develop ‘right-first time’ configurations online that are then delivered ready-made for use in the target application.

“The configurator, which covers our four hi-reliability families, will be fully integrated into Harwin’s automated processes. It will allow engineers to develop fully functional configurations that are guaranteed to be to specification and that can be supplied in with very short delivery times,” explained Peter Schneid, Harwin’s VP of Marketing. “We want to make developing cable assemblies as simple as possible, freeing up the designer's time to focus on product development.”

As technology evolves so too does the need for cable harnesses that can handle increasingly complex requirements. Consequently, engineers are faced with challenges like creating designs that fit smaller, more efficient devices, adapting to the rise of the IoT, and making systems more flexible and modular.

“Cabling is a very complex topic,” said Schneid. “For many engineers it’s not their area of expertise and, very often, as it’s not a core skill they find that when they reach this point in the design process they come up against significant challenges. As a result, the design takes longer than it should. Our tool is intended to help the engineer get their thoughts in shape and to better understand the components and tools required.”

There are number of significant trends impacting cable harness design such as miniaturisation and modularity, according to Schneid, and these trends are evolving rapidly. What was once a hands-on process has now embraced automation and smart technology, significantly improving both efficiency and performance.

“Consequently, design engineers have significantly greater expectations and are looking to suppliers like Harwin to provide reliable connections, ensuring durability as well as the ability to handle increasingly complex systems where signal integrity is critical,” said Schneid.

The automotive, aerospace, and electronics sectors are reliant on high-quality harnesses to ensure seamless power and signal transmission, and they will often need to be able to operate in challenging environments. Cable harnesses are now key players in driving technological innovation.

The rise of smart manufacturing and greater automation means that the Cable Configurator hasn’t simply been ‘bolted on’ to a manufacturer or third-party website but has been developed as a ‘support infrastructure’ that fully integrates with Harwin’s existing ordering and manufacturing processes.

“What we are creating is a design and procurement process that’s seamless, intuitive and as fast as possible,” Schneid explained.

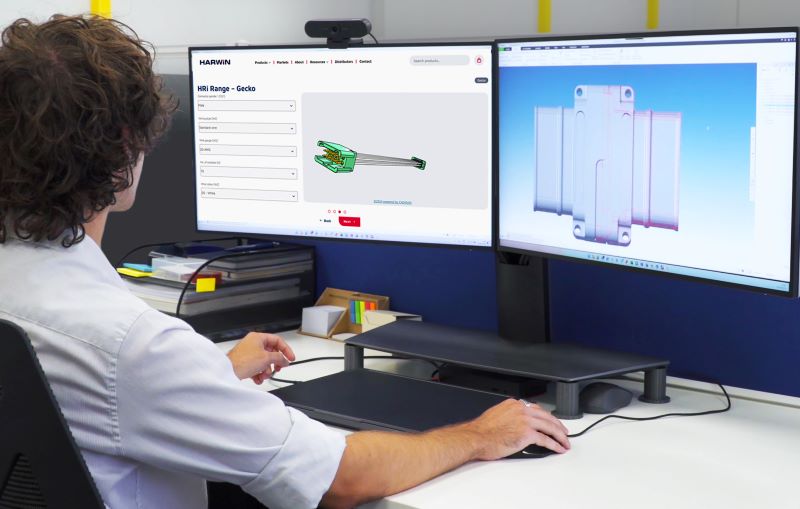

Above: Harwin’s Cable Configurator tool provides a visual guide for engineers

Today’s engineers are tasked with delivering the performance and reliability demanded by the target application while addressing so-called SWAP demands and are often required to do so with fewer resources.

“Harwin’s tools help by simplifying the process of selecting and sourcing products that are optimised for application-specific and SWAP criteria but also by making subsequent application development and prototyping much easier,” said Schneid.

The Cable Configurator provides an on-demand service that dramatically reduces the time needed for product selection, application prototyping and, ultimately, purchasing.

“We have been investing heavily in our online presence,” explained Schneid, "and have focused on improving the user experience. I think we are now delivering a retail level of experience that users will have grown to expect from the likes of Amazon.

“The Cable Configurator comes in several stages. The first allows engineers to select the product family they require, much like they would on any retail website. Once they have made their selection, we can create a real-time render of their design to show them how the project might appear in reality,” explained Schneid. “Throughout the process we will be recommending and highlighting complementary products that could support the design.”

The Cable Configurator is a visual aid that will help the engineer to see what they are designing, and it can provide a summary of the components selected. By simply selecting a few key design parameters, engineers will be able to configure Harwin’s high-performance, high-reliability connectors in a single- or double-ended cable assembly.

“At that point they can then download a 3D rendering along with a technical drawing, a full bill of materials and, ideally, the option to request a quote,” added Schneid.

The user experience and the quality of the data that is made available to the engineer will determine how engineers use the tool and whether they will then look to source components from Harwin.

“That experience has been critical and is at the heart of the platform,” explained Schneid. “A good user interface will help us to increase the chance of an engineer re-visiting and ultimately sourcing our connectors and cabling solutions.”

Advanced online tools make product selection and application development faster and they are being used at a time when the support engineers require is changing, according to Schneid. “We have service levels in place that require us to respond to requests made via our website in 12-24 hours and if someone is looking for a quote, we can turn that round within 72 hours. A lot of companies are looking at artificial intelligence and use chatbots, but with Harwin you are guaranteed to speak with a technical expert – and that’s because most of those enquiries are around a customised design.

“There isn’t a clear use case for AI, in our opinion. You need sound data to service base models and that data isn’t good enough just yet. We believe that a human is still able to do a better job.

“We need to engage with engineers on their own terms. They will want to do their own research, make their own selections and only then contact us as the supplier.”

Looking to the future cable harness designs will need to keep up with the rapid pace of technological advances - a lot of existing solutions will have to be adapted or upgraded.

Environmental concerns are going to become more important, with a need for more sustainable materials and energy-efficient solutions. In future harness designs will likely have to incorporate recyclable materials and energy-saving features.

Finally, as systems become more complex, so the importance of rigorous safety standards and high-quality design will continue to grow.

All of which suggest that tools like the Cable Configurator will become more important and have a critical role in aiding design engineers.

“Engineers are not going to have a deep expertise across their entire design, so we are there to support them in a relatively narrow design space which often comes late in the process at a point when the design has already been approved. The Cable Configurator is there to help them at a crucial point in their journey and to ultimately help them make the right choices for their design,” concluded Schneid.