Large battery packs are made up of battery cells connected in series to form high voltage stacks.

Batteries lose capacity with time and use, and batteries within a large pack lose capacity at different rates. This is because of differences within the cells as well as exposure to varying operating conditions such as thermal gradients. The differences in battery aging cause mismatches in capacity from cell to cell within a stack that grow over time. Unfortunately pack capacity is limited by the weakest cell in the stack.

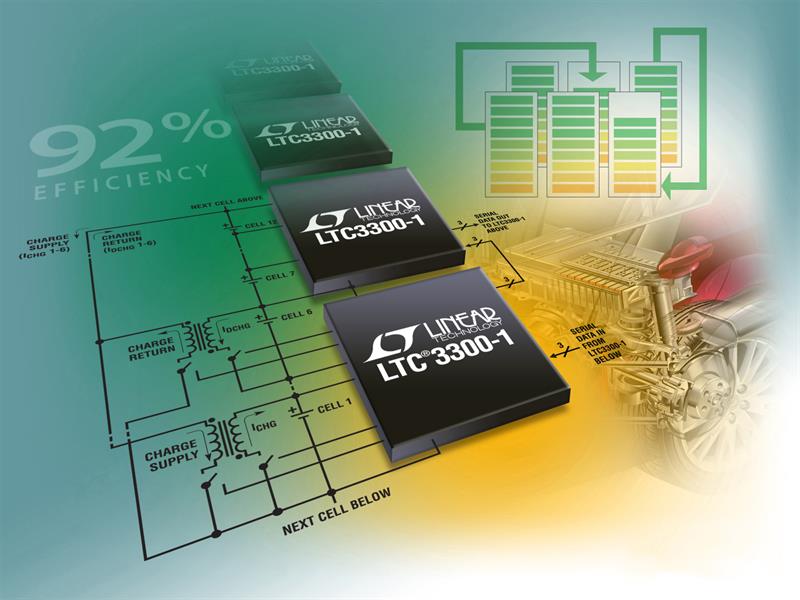

Traditional passive battery balancing can only protect the stronger cells during charging, creates heat in the process, and cannot compensate for weak cells. Alternatively, active balancing adds the capability of transferring charge from stronger cells to weaker cells, increasing pack capacity and run time. Recently, integrated controllers such as Linear Technology’s LTC3300 offer high balance currents and high efficiency.This is a bi-directional, active battery balance controller that can balance up to six series cells independently and simultaneously.It manages currents up to 10A at greater than 90% efficiency.

Automotive electronics

The automotive market for analog electronics is growing rapidly, is forecast to maintain growth greater than that of the overall industry for at least the next several years and has grown to 20% of Linear’s business. Electronic systems are transforming the transportation experience with growing expectations for connectivity, convenience, safety and fuel efficiency.A typical mid-size vehicle now contains more than 100 processors and dozens of motors, as electronics replace traditional electro-mechanical and hydraulic systems.The proliferation of distributed systems and diagnostics in vehicles places greater demands for digital communications, which in turn drives higher data rates and increased demands on digital transceivers.

Historically, linear voltage regulators have been used to provide regulated power for digital processors, transceivers and related components.But as power demands increase, use of linear regulators is increasingly problematic.Linear regulators are simple, low cost components that have very compact, easy-to-design application circuits.But these regulators have poor efficiency when converting an automotive battery voltage to the low voltages required for digital components.For example, linear conversion from 12V to 5V yields a conversion efficiency of 42%, and 12V to 3.3V conversion yields less than 28% efficiency.If the power supply load is, for example, 280mW at 3.3V, 1W of input power is required, resulting in 720mW lost as heat.Managing system efficiency and the resulting thermal stress is a growing focus for automotive system designers.

One alternative for system designers is to use a switch-mode DC/DC converter in place of the linear regulator.Switchers are highly efficient, but bring their own challenges, including selection and sourcing of inductors, loop compensation, mitigation of radiated EMI and a relatively complex and large solution footprint.

A second alternative to traditional linear regulator applications is switched-capacitor charge pump regulators.These components share the compact solution and simple to use advantages of linear regulators while bridging the efficiency gap between linear and switching regulators.Linear Technology offers a family of high voltage-capable charge pump regulators that are well suited for these applications.For example, the LTC3255 is capable of servicing a load up to 50mA from an input voltage range from 4V to 48V, fault-protected from -52V to 60V.Its no load quiescent current is just 20µA.Efficiency from 12Vin to 5Vout is over 80%, and from 12V to 3.3V is 55%, resulting in only about 50% of the power loss generated by a linear regulator.Unlike linear regulators, charge pumps are also available for inverting and buck-boost applications.

Wireless sensor networks & energy harvesting

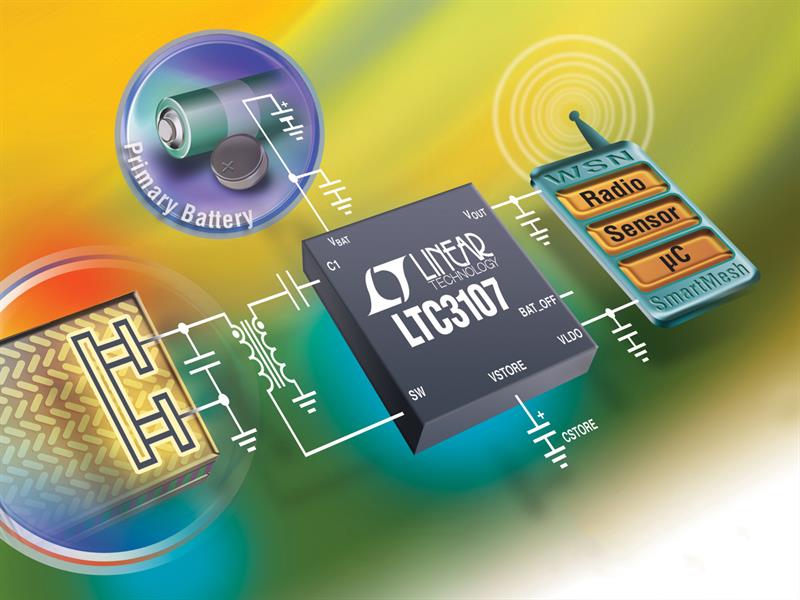

The introduction of robust and ultra-low power wireless sensor networks, like those enabled by Linear Technology’s Dust Networks SmartMesh product lines, is transforming the way sensors are deployed in applications ranging from environmental monitoring to transportation infrastructure to the factory floor.And as sensors are deployed in remote, isolated or dangerous environments, the potential to power them from local ambient energy, free from wires and free from service, is here today.

Linear Technology introduced the first energy harvesting integrated circuits specifically designed to condition power from low level solar, piezoelectric and thermo-electric generator (TEG) outputs in 2010.Since then, we have brought to market a family of products that allow the user to supplement a primary cell or rechargeable battery with harvested ambient energy, increasing the system run time indefinitely, or approaching the shelf life of the primary cell.These products handle all aspects of the power system, including DC/DC conversion, PowerPath control and local energy storage.One example, the LTC3107, conditions energy from low voltage, low impedance sources, including TEGs and thermopiles, converting inputs as low as 20mV into power suitable for powering a remote sensor node.It provides seamless transitions between the harvested energy and a primary cell battery, giving priority to the ambient energy source and drawing just 80nA from the battery when the harvester is active.Practical and efficient energy harvesters are a key component to bring the Internet of Things from concept to reality.

Author profile:

Don Paulus is vice president, Power Management Products, Linear Technology Corporation