Nevertheless, most current generation electric vehicles (EVs) are still considered as expensive or less attractive when compared to conventional combustion engine cars. Consequently, cost reduction and improved performance are key to ensure a successful and sustainable market growth. Reduction of size, weight, and cost impacts the competitive edge of battery systems over a vehicle’s complete lifecycle. On the other hand, the extension of the driving range will also have a significant impact on their market attractiveness and competitiveness.

In addition, the increasing numbers of EVs reaching the end of their life, means that manufacturers will even be competing for the value to be derived from second life batteries recovered from scrapped vehicles.

Out of this demand, news about battery innovations tends to highlight the new battery packaging concepts and new materials that might one day be able to store more charge than today’s lithium technology. A different part of the battery - the battery management system (BMS), which monitors the state of charge (SOC) and state of health (SOH) of the battery - tends to go under the radar but needs to follow and support battery innovation.

A wireless BMS (wBMS) technology, developed by Analog Devices and pioneered by General Motors in its modular Ultium battery platform, is now in mass production.

The wBMS gives car manufacturers a competitive edge across the whole of a battery’s life - starting from when battery modules are first assembled, to operation in an EV, beyond to disposal, and even, if needed, into the battery’s second life.

Wired battery connections

The intention for the wBMS technology development was based on an analysis of the drawbacks of the communications wiring in today’s conventional EV battery packs. This analysis drew on ADI’s experience as it supplies highly accurate BMS ICs in the field of wireless communications, the company has also developed a robust mesh networking technology for industrial environments.

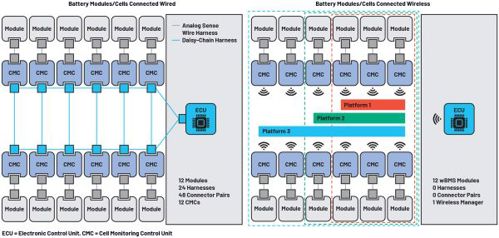

In a conventional EV battery pack, each cell is measured by a battery management IC. Data from the battery management IC are then communicated back to the pack ECU through wiring. This requirement for communications inside the battery reflects the complex architecture of a large battery pack: it is typically made up of modules, each of which contains multiple cells. Natural production variations mean that each cell has individual characteristics that vary within a specified tolerance range. To maximise battery capacity, lifetime, and performance, the key parameters of battery operation - voltage, charge/discharge current, and temperature - need to be monitored and logged individually for each module.

Consequently, EV batteries require a means to transfer data from each module or cell, where voltage and temperature are measured, to the ECU processor. Traditionally, these connections have been made with wires as they have the advantage of being familiar and well understood.

Disadvantages of a wired BMS

However, there is also a list of disadvantages related to wires: a copper wiring harness adds additional weight and occupies space that, if filled by a battery cell, would provide extra energy capacity. Additionally, the wiring needs to be fastened on battery housing structures and connectors can potentially suffer from a mechanical failure especially under vibration and shock conditions.

In other words, wires increase development effort, manufacturing cost, and weight while also reducing mechanical reliability and usable space. This results in reduced driving range. By removing the wiring harness, the car manufacturer gains new flexibility to meet a vehicle’s design requirements for the form factor of its battery pack.

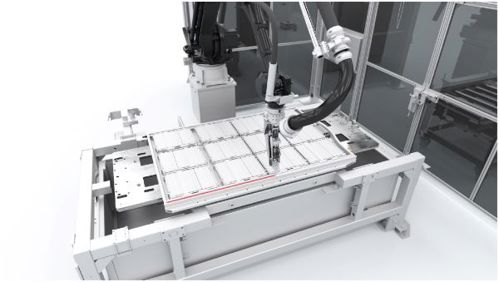

The complexity of a battery’s wiring harness also makes the assembly of a battery pack difficult and expensive - wired packs have to be assembled and the connections have to be terminated manually. This is a costly and hazardous process because high voltage EV battery modules are supplied charged. To maintain the safety of the assembly process and to protect production line workers, rigorous safety protocols are applied.

Out of those reasons, there are, then, strong reasons for OEMs to introduce a robust wireless technology in new EV battery system platforms.

Figure 1. A typical multicomponent wired BMS network (left) and the simpler arrangement made possible by wBMS technology (right).

A smart approach

The wBMS is a complete solution that is easy for the automotive manufacturer to integrate into a battery pack design. It includes a wireless cell monitoring controller (wCMC) unit for each battery module and a wireless manager unit to control the communications network, which connects multiple battery modules wirelessly to the ECU. Beside the wireless section, each wCMC unit includes a BMS that performs highly accurate measurements of various battery parameters so that the applications processing unit can analyse the SOC and SOH of the batteries.

While the wBMS technology has taken full advantage of eliminating the wiring harness design and assembly issue, there are further areas within the battery lifecycle where additional value will be generated:

Battery assembly - the only connections that a battery module requires are the power terminals, which can readily be made in a highly automated process. By eliminating manual labour for assembly and testing, this also avoids safety risks to assembly line workers. Furthermore, the modules can also be tested and matched before installing inside the battery.

Servicing - secure wireless capability means that the condition of the battery pack can be conveniently analysed by diagnostics equipment in an authorised garage without touching the pack. If a malfunction is detected, a faulty module can easily be removed and replaced. A wireless configuration simplifies installation of a new module in the battery system.

Second life - by the increasing number of vehicles, a market is emerging for second life batteries recovered from scrapped EVs and repurposed for applications such as renewable energy storage systems and electric power tools. This additionally creates a new source of value for EV manufacturers, which are responsible for the recycling or disposal of the batteries in scrapped EVs since wBMS allows a simpler integration of the modules for second life applications.

Disposal - the recyclable metal and potentially hazardous materials inside a battery pack require approved and regulated disposal arrangements. The simple connections and absence of a communications wiring harness make removal of battery modules easier and quicker than that of a wired battery.

Data management - the wBMS technology makes it easy to read out critical battery data from each intelligent module: this means that the condition of the batteries can be determined individually. These data can, for instance, provide information about the SOC and SOH of a module. In combination with data from when the module was originally produced, this allows the optimal usage in its second life application and the provision of a detailed set of specifications for each module on sale. The ready availability of these data increases the resale value of the modules.

Figure 2. The wBMS eliminates the BMS signal wiring harness to enable automated, robotic production of battery packs.

Complete solutions

The wireless network protocol implemented by ADI in the wBMS system has the automotive industry’s requirement for reliability, safety, and security under all operating conditions based on the network-wide time synchronisation technology. The use of the wBMS in a mass production EV from General Motors is a proof of its reliability in the harshest environments: the wBMS-based battery has been run over hundreds of thousands of kilometres in more than 100 test vehicles under the toughest conditions.

With the wBMS, ADI also supports automotive manufacturers’ programmes in compliance with the ISO 26262 functional safety standard. The radio technology and the networking protocol have been developed in such a way that the system is resilient in noisy environments and provides secure communication between the monitoring units and the manager using a sophisticated encryption technology. The security measures avoid spoofing of data transmitted on the wireless network by an unintended recipient such as a criminal or hacker. Furthermore, the transmitted data are received without any modification of the contents, and the intended recipient knows exactly which source has sent a message.

Lifetime management

Across the entire battery pack’s lifetime, from initial assembly through disposal to second life, the wBMS capability embedded in the battery pack ensures that the vehicle’s manufacturer and its owner can easily track the condition of the battery, maintain the performance and safety, and maximise the value. The entire system, including the interactions between the battery modules’ cell monitoring units and the ECU, is handled by ADI’s technology, with configuration settings defined by the manufacturer.

The wBMS technology is also backed by ADI’s battery lifecycle insight service (BLIS) technology. This provides edge-based and cloud-based data software to support traceability, production optimisation, monitoring in storage and transit, early failure detection, and lifetime extension. Together, the wBMS and BLIS technologies enable automotive manufacturers to gain higher returns on their investments in battery pack development and production, improve the economics of their EV business strategies, and help accelerate the market’s shift toward a low carbon, sustainable future for personal mobility.

The key to designing and enabling such battery solutions with wBMS are system understanding as well as methods and tools that support the design and technologies as described before.

AVL offers the full range of simulation, testing, engineering capabilities, and experience to successfully drive these innovations together with their customers and bring them into the market by making them ready for series production. AVL is currently strongly working on battery ecosystem solutions through developing data analytics methodologies, predictive functionalities supported by using virtual development, and vehicle and battery data in order to increase the lifetime and performance of batteries.

Author details:

Stephan Prüfling, Product Manager, Battery Management Systems at AVL

Norbert Bieler, Director, Business Development E-Mobility at Analog Devices