These solutions are diverse, although they all share a goal to use less energy - especially energy generated using non-sustainable methods. While no single approach will solve the issue, each step forward is a marginal gain that contributes to the overall solution.

Sustainability can take many forms, from promoting the growth of environmentally friendly energy forms (such as solar and wind) to ensuring that this energy is used as efficiently as possible.

Even with the availability of ‘clean’ energy, avoiding all types of waste is key to a sustainable future such as that described in the United Nations’ Sustainable Development Goals (SDGs).

The technology that has become essential to our daily lives consumes significant energy. This is particularly true for electric motors that are commonplace and consume 40% of the world’s energy.

However, the technology sector is also making significant contributions to sustainable living through activities such as developing more efficient semiconductor devices and enabling monitoring of our energy usage.

Sustainability in the Design Process

The design phase is crucial in defining how a product operates. This means that sustainability begins here, and designers must make decisions that support this goal, delivering efficient use of energy and low consumption during any standby operation.

Fortunately, device manufacturers are creating components and sub-systems with excellent sustainability credentials. This includes components such as microcontrollers, wireless communication modules, and a huge variety of power-oriented components.

Alongside this are several development tools that assist designers to optimise energy usage of a new design. One such device is the Qoitech Otii Ace Pro Power Supply and Measuring Instrument (Figure 1). This small device measures voltage and current at a high sample rate and can precisely source voltage.

Figure 1: The Otii Ace Pro is an invaluable tool for analysing energy usage when developing sustainable solutions. (Source: Mouser Electronics)

The Otii Ace Pro features a battery life estimator, real-time analysis, and fully configurable UI. With this tool, designers can measure and record power consumption, leakage current, and sleep current. Armed with this data, they can make sustainable choices.

Naturally, any technology associated with the creation and transformation of energy is being scrutinised for its sustainability credentials. Nowhere is this truer than in the world of power semiconductors.

Low-Loss Semiconductor Technologies for Power Applications

For decades, silicon has been the basis of all power devices. With the need for ultimate efficiency, especially in areas such as sustainable wind- or solar-based power generation, silicon's ability to meet design goals is diminishing. New wide-bandgap materials such as silicon carbide (SiC) offer lower losses, high-temperature operation, and reliability.

For example, inverters are a key component in converting the DC power from solar photovoltaic panels into AC for the grid. State-of-the-art silicon inverters can achieve 98% efficiency, while SiC-based inverters increase this to 99%. While this may seem small, it represents a halving of the losses and, with 60 gigawatts (GW) of solar power installed in the United States, this 1% gain represents an additional 600MW of available solar energy. When applied to Europe’s 208.9GW of solar farms, the gain from SiC technology would be around 2089MW.

Of course, there are many applications for SiC technology, including in electric vehicles (EVs), where efficient and robust performance ensures better range on a single charge. One of the broadest SiC portfolios available is from onsemi, whose M3S EliteSiC MOSFETs are designed for high-frequency applications to optimise performance and efficiency. Compared to previous generations, these devices offer around 40% lower total switching losses, making a significant contribution to system efficiency.

Sustainability in Industrial Applications

While we may constrain our consumption habits in the future, we will always need to consume. To improve sustainability in this area, the factories that produce these goods must become more sustainable in their operation. The Internet of Things (IoT) and its close cousin, the Industrial IoT (IIoT), are allowing ultra-low-power sensors to be placed around factories and warehouses to monitor and control energy usage in areas such as lighting.

Lighting is required only when humans are present, with many fully automated facilities operating entirely ‘lights out’. Operating lights manually via switches is not the most sustainable option as they will inevitably be left on, wasting energy. Using IIoT sensors to detect the presence of humans and control lighting accordingly eliminates waste and reduces operating costs.

Maintenance is an important area of factory operation, ensuring machines operate at their optimum performance and do not break down, which can cause stoppages and reduced output. Typically, maintenance is performed on a time schedule (stipulated by the machine manufacturer) based upon an estimate of when it may be needed. However, this is not the most sustainable approach as it is based upon time and not need.

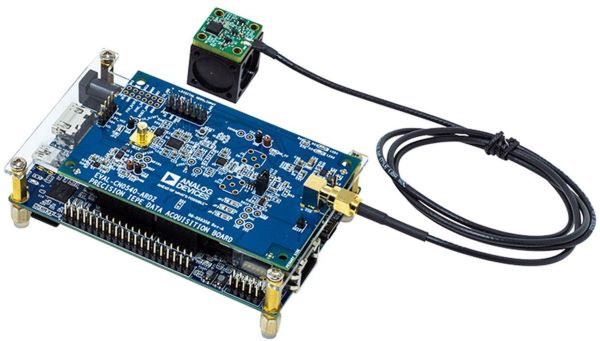

As most machines more quickly show wear around their moving parts, vibration and sound are the two measurable phenomena that can indicate a requirement for maintenance to be carried out. Analog Devices’ CN0549 condition-based monitoring development platform (Figure 2) - featuring the CN0540 IEPE Data Acquisition Board, CN-0532 Circuit Evaluation Board, and EVAL-XLMOUNT1 Mounting Block - measures vibration with an accelerometer, allowing for the collection of large datasets to establish a baseline for the machine.

Figure 2: Analog Devices’ CN0549 development platform allows maintenance to be planned sustainably, based upon need. (Source: Mouser Electronics)

Using an algorithm or a simple threshold, crews can monitor the need for maintenance. This is the most sustainable approach as it eliminates wasteful early maintenance while ensuring that wear is detected and addressed before it can lead to an expensive machine failure.

Summary

Sustainability is essential to addressing environmental issues, including climate change, and many sustainability initiatives are under way. The electronics industry will play a significant role in such initiatives, ensuring the efficient production of renewable energy, designing devices that use as little energy as possible, and ensuring factories do not waste resources - especially in maintenance.

Author details: Mark Patrick, Director of Technical Content, EMEA, Mouser Electronics