But there are other FPGA developers and their target markets are, in general, different. Kambiz Khalilian director of Lattice Semiconductor's industrial and automotive segments, said: "Our focus is not on creating the fastest, largest FPGAs. While Altera and Xilinx are looking at telecomms, Lattice is looking at high volume, low cost applications and at providing an alternative to ASICs, which many companies say are too expensive and therefore are looking for another solution."

The strategy, put in place by CEO Darin Billerbeck, started with the acquisition in 2011 of SiliconBlue and its iCE family. Recently, Lattice acquired Silicon Image for $600million, bringing a slightly different range of capabilities to the company.

The industrial market is an obvious target for Lattice. "We're looking at the market segments," Khalilian noted, "working out where we have strengths." Amongst the opportunities which have been highlighted are interfacing displays and image sensors to host processors. "The sectors where we see growth opportunities include surveillance and cameras in general," he continued. "But Lattice is not an image sensor company; we use interface technology."

One of the issues which system developers face when integrating displays and image sensors is linking them together. "Traditional image sensors have been equipped with parallel interfaces," Khalilian explained. "But the growing demand for high definition has pushed the need for serial interfaces. However, there has been no standard for these interfaces, which means everyone created their own different 'flavours'."

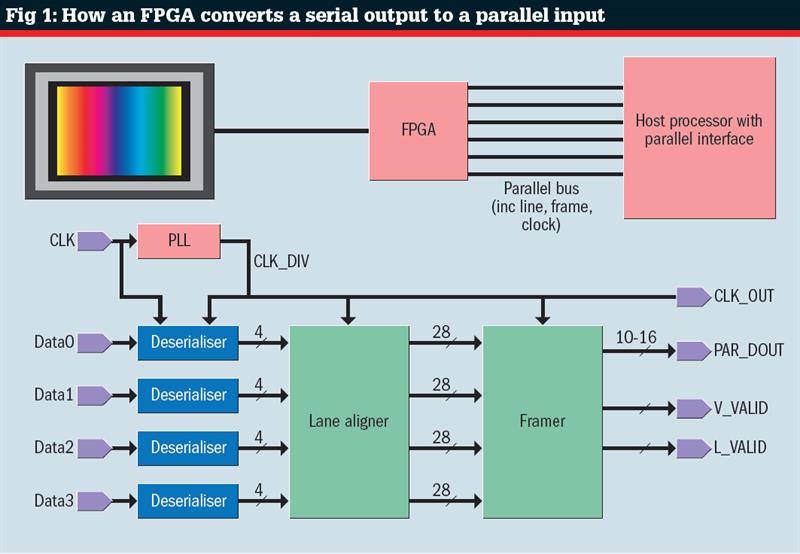

This seemingly random approach has created a mismatch; not all sensors support all interfaces and not all processors support all interfaces. A possible solution is to use FPGAs in a way which recalls how their predecessors were used as 'glue logic'. "Low cost FPGAs can be used as a bridge between the two," Khalilian asserted (see fig 1).

Lattice also sees potential in enabling industrial customers to take advantage of components developed for mobile devices. "Take image sensors as an example," he said. "The mobile world has standardised on the MIPI interface and image sensors for mobile applications use the MIPI CSI-2 interface. But some designers use industrial sensors and mobile processors and vice versa."

Khalilian sees a similar thing happening with displays. "A lot of consumer displays are now available at attractive prices and industrial application designers want to take advantage of this. These displays have MIPI DSI interfaces or Embedded DisplayPort and create another mix of interfaces. Because these don't match, you can use an FPGA for bridging – and maybe some additional processing."

A further complication comes from growing demand for solutions with multiple sensors. "While there may be multiple sensor feeds into a host processor," Khalilian pointed out, "the processor might only have one interface; some may support two. But automotive applications are using five or seven cameras, whilst surveillance is moving towards panoramic images. Gesture recognition needs at least two cameras. All of these applications increase the need for flexible interfaces."

FPGAs bring a bonus; besides doing the necessary interface conversion to link seemingly incompatible parts, they can also allow designers to include more functionality.

"You can do more with an FPGA," Khalilian said, "but it depends on what size device is selected. Simple interfacing – for example, a MIPI CSI-2 output to a parallel input – can be handled by an FPGA with 1200 look up tables. However, using an FPGA with more capacity allows additional processing to be undertaken. Designers can add a larger FPGA and differentiate their product by adding new features."

One such feature is wide dynamic range (WDR), something which Khalilian said is being supported by newer sensors.

"When you take a picture, there are always bright and dark parts," he said, "so it's always a compromise. WDR takes multiple images – at least two – using high and low exposures. Low exposure shows details in bright areas, while high exposure shows details in dark areas. The images are put together using tone mapping to create a single WDR image, with all the details visible.

"It's a key feature in surveillance applications," he continued, "where you might be looking for people hiding in the shadows. And it's needed in automotive systems in order to detect all the objects in a field of view."

Processing these images requires a lot of power and there may not be enough horsepower available from the host processor to create the WDR image in real time.

"It's a feature in the latest iPhones," he noted. "But the image takes a few seconds to appear. In a security application, you have to do it in real time. So it makes sense to use an FPGA for preprocessing and to feed the results to the host processor."

He also pointed to low light enhancement. "In low light, images will have a lot of noise. This needs to be removed and the image enhanced. You could use a small FPGA to do the minimum amount of work, but some apps will want to use more algorithms. In this case, a larger FPGA can be selected and a complete camera pipeline implemented."

USB connectivity – particularly for the recent USB3 implementation – is another potential application with Lattice is looking to exploit. "Our acquisition of Silicon Image means we can now offer an ASSP style solution to the problem."

Khalilian said the same issues applied in the connectivity sector as were found in displays and sensors. "USB controllers usually feature a generic interface," he suggested. "If you want to convert an image and output it over a USB3 port, the controller can't support all possible formats, so an FPGA is a good solution. We also support various audio and video formats that can be 'understood' by a generic USB3 controller."

Looking to support the time to market issues which designers of such systems as mentioned face, Lattice has a range of reference designs – not only for FPGAs, but also at the board level. "Our strategy is to support engineers with production ready reference designs," Khalilian explained. "In the FPGA world, a reference design is something that goes into the FPGA. It's effectively a piece of code that is pushed through the toolchain and can be used with any part in a particular family.

"But we're also targeting new customers with little or no FPGA design experience. While these companies might be good at designing PCBs and selecting chipsets, they don't usually have FPGA designers or tools; they don't want to make a big investment. With a board level reference design, they don't need to program."

Lattice is likely to be expanding its interface offerings in the future, building on the Silicon Image acquisition. "We're beginning to think about programmable ASSPs," Khalilian concluded. "These parts will have an FPGA fabric, but they will also feature things like hard interfaces that application developers are specifying."