From smartphones to aerospace technologies, this specialised technique forms the backbone of semiconductor manufacturing and microelectronics, enabling the creation of reliable, high-performance components. Over the years, wire bonding has evolved, driven by advances in materials and methods - such as the shift to smaller or lighter, more conductive materials - that have improved efficiency and performance in countless applications.

As technology progresses, the role of wire bonding continues to adapt. These advancements have expanded the possibilities for more precise and efficient sensing technologies, pushing the boundaries of what’s possible in electronics.

So, what is the history, innovations and future of wire bonding? This article takes a closer look at how this unsung hero of electronics is crucial to the continued evolution of modern technology.

A rich history of precision and progress

Wire bonding dates back to 1957, when it was first presented by Bell Laboratories. The original method, known as thermocompression bonding, involved using pure gold wires and applying heat upwards of 300°C, combined with pressure, to create bonds. While effective, this high-temperature approach limited the range of chips that could be processed without damage.

In the 1960s, ultrasonic bonding emerged to address these limitations, introducing high-frequency vibrations to make connections at lower temperatures. This method opened up new possibilities, leading to the development of thermosonic bonding, which uses a combination of moderate heat and ultrasonic energy, reducing thermal stress on components. These innovations made wire bonding more versatile and paved the way for modern manufacturing.

Ball bonding and wedge bonding are the two primary techniques developed over the decades. Ball bonding, ideal for high-density applications, uses a small gold ball formed at the end of the wire, while wedge bonding, more suitable for aluminium wire, uses ultrasonic energy to create a connection.

Both methods have remained fundamentally unchanged in principle, yet their precision and efficiency have improved drastically.

Material advancements

Gold has been the standard for wire bonding due to its excellent conductivity and malleability. Yet, the high cost of gold has driven the industry to explore more affordable materials. Aluminium, especially a 99% aluminium alloy with 1% silicon, became a strong alternative for wedge bonding, offering a cost-effective and reliable option.

In recent years, copper has gained attention as a promising material. Its superior conductivity and strength make it a compelling alternative, though it brings challenges like oxidation and increased bonding difficulty. Copper wire bonding requires careful process control to overcome these hurdles. Insulated and coated wires, such as palladium-coated copper, are also being developed to prevent short circuits and improve performance in densely packed circuits.

At Solsta, we use both gold and aluminium wires for specific legacy products. As demand shifts and the need for higher efficiency grows, we're exploring options to transition to more cost-effective and robust materials, especially as clients increasingly prioritise performance and cost-efficiency.

Meeting the challenges of miniaturisation

Miniaturisation remains one of the most significant trends shaping electronics manufacturing. As components shrink and circuits become more densely packed, wire bonding must adapt to ensure reliability and performance. Today’s automated bonding equipment boasts incredible precision, with accuracy measured in single-digit microns. At Solsta, we have invested in modern desktop wire bonders with accuracy levels of ±5 to 10 microns, a massive leap from the manual processes of the past.

The challenge of miniaturisation is not just about precision. As wire diameters decrease, bond strength and reliability become increasingly difficult to maintain. Using ultrasonics and controlled pressure on these finer wires require a delicate balance. Smaller wires, known as ultra-fine wire bonding, which start at 10 microns, introduce significant stress management issues, requiring innovations in both materials and techniques to ensure bonds remain strong and effective.

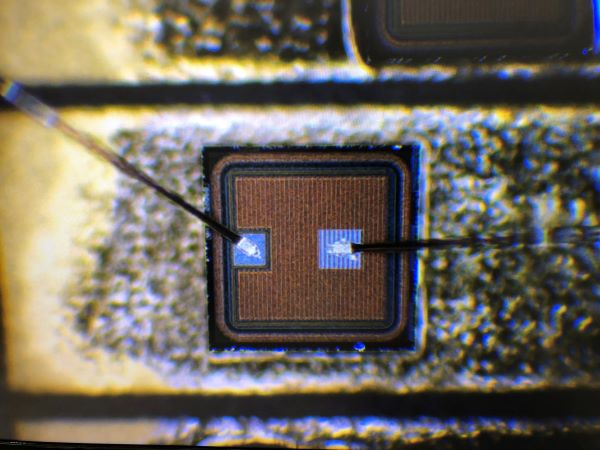

Above: A close up of wire bonds on a chip

Competing technologies

With alternatives like flip chip bonding and 3D interconnects emerging, one might wonder whether wire bonding’s dominance will diminish. Flip chip bonding, for instance, uses solder bumps to connect chips directly, saving space and reducing resistance. It has been around for over a decade and is well-suited to high-density applications where every millimetre counts. Despite this, wire bonding has not lost its relevance. It remains widely used, particularly in applications that demand proven reliability, such as aerospace, defence and medical technology.

Wire bonding continues to hold a strong market position, likely representing over 75% of interconnect applications. Its endurance is partly due to its adaptability and the extensive industry standards that underpin its reliability. Standards such as military and space specifications give manufacturers and engineers the confidence that wire bonds will perform under the harshest conditions, where failure is not an option.

Shaping the future

The future of wire bonding will likely involve the integration of new materials and equipment innovations. Copper wire, in particular, stands out as a cost-effective and high-performance alternative to gold. Companies are also experimenting with different compositions and coatings to minimise oxidation and improve reliability.

Another exciting development is ultra-fine wire bonding. Traditionally, we have categorised wires as fine or heavy. Heavy wire bonding, which can use wires up to 500 microns in diameter, is crucial for high-power applications. Fine wire bonding typically involves 25 to 32-micron wires. However, as the push for smaller, more compact devices continues, ultra-fine wires, possibly as thin as 5 microns, could become standard. The development and adoption of these wires will depend heavily on advancements in bonding equipment and process monitoring.

Modern wire bonding machines now incorporate features like pattern recognition and automated quality checks. These advancements allow for real-time monitoring of bond deformation and other critical parameters, ensuring each bond is consistent and reliable. At Solsta, our commitment to using advanced statistical process control has improved yields and product quality, benefiting both our clients and end-users.

The lasting importance of wire bonding

Wire bonding may be a mature technology, but its relevance is as strong as ever. It remains a reliable and adaptable solution, essential to a wide range of industries. We need to commit to continuous improvement, leveraging both tried-and-true methods and new innovations to optimise our processes and ensure the highest quality for our clients.

The expertise and dedication to wire bonding at Solsta are a testament to the importance of this technology. Our team’s work goes beyond routine manufacturing; we engage in rigorous testing and optimisation to ensure every product is made with precision and reliability. This process-driven approach not only improves efficiency, but also reinforces our reputation as a trusted partner in high-stakes sectors like medical technology and defence.

As we look to the future, the goal is clear: to keep refining, adapting, and innovating so that wire bonding continues to meet the demands of modern technology. We need to ensure that this essential, yet often unsung, process remains a key driver of technological progress.

Author details: Kit Moore is Lead Process Engineer at Solsta