The Tessent® TestKompress® with Automotive-grade ATPG software tool addresses the need for very high-quality ICs for automotive electronics by targeting defects within cells, at the transistor level. Traditional test methods are designed to capture defects in the interconnect between cells, and therefore miss a large, and growing, number of defects that occur in today’s complex transistors. Capturing these otherwise undetectable defects helps the makers of digital ICs meet the ISO 26262 goal of zero defective parts per billion (DPPB).

Tessent TestKompress with Automotive-grade ATPG contains a suite of fault models and test pattern generation applications that can be used separately or together. The software is the result of decades of research in cell-aware, layout-aware, and defect-oriented test and modeling. These technologies were developed in collaboration with foundries, fabless companies, and integrated device manufacturers (IDMs). Tessent TestKompress with Automotive-grade ATPG has been validated on millions of tested devices representing mature planar process nodes, as well as state-of-the-art FinFET processes.

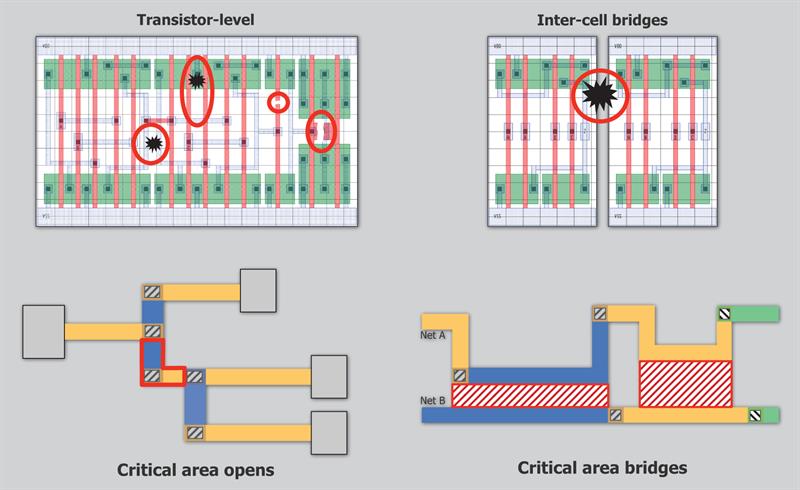

Figure 1: Automotive grade APTG target defects at the transistor level inside cells, between adjacent cells and in the interconnect

With Tessent TestKompress Automotive-grade ATPG, users can target not only the cell-based faults, but can also start to introduce the same layout-based technology to address critical area-based interconnect and cell-neighborhood faults. Enabling structural test to reach DPPM levels that would otherwise only be possible by combining ATPG patterns with extremely expensive functional or system-level tests.

Mentor’s fault model extraction makes TestKompress cell-aware stand out from the crowd.

The fault extraction uses layout- annotated Spice representation of the cells to identify the location of possible transistor, bridge, open, and port defects. The extraction process automatically ranks bridges and opens on critical area, allowing ATPG to focus on the most important defect locations.

As the automotive electronics industry creates larger and more complex chips at the most advanced process nodes, they can rely on the Tessent family of products from Siemens to help them meet their required IC quality.

To learn more, follow the links at the bottom of the page to either download the white paper or visit the product website.